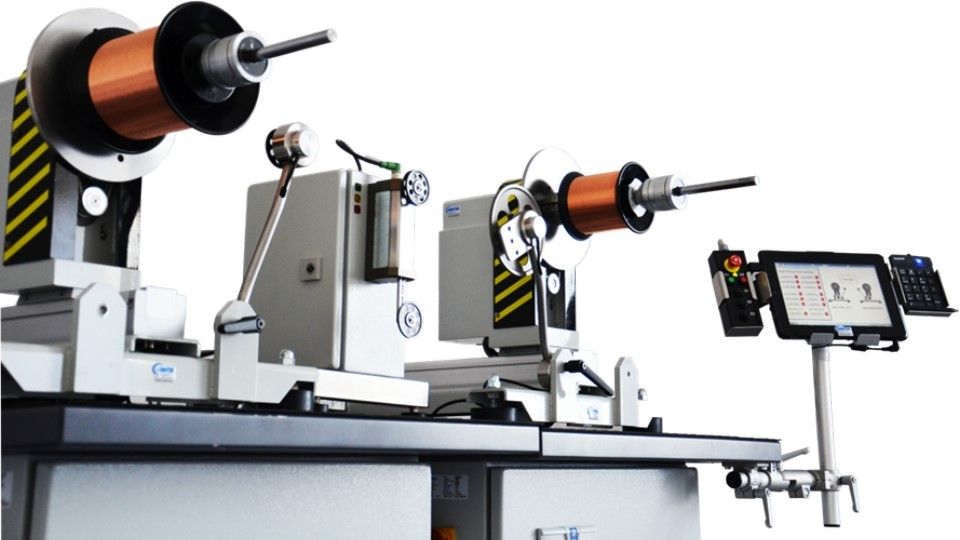

Payoff winder

Payoff Winders are industrial machines designed for unwinding and winding materials such as wires, cables, optical fibers or other linear materials. It plays a crucial role in manufacturing processes where precise handling and smooth material transfer are required. Payoff winders are used across various industries, including telecommunications, electronics and automotive, ensuring optimal performance and efficiency during material processing.

Key Features:

- Precision Control: Equipped with advanced tension regulation systems to maintain consistent material flow without stretching or deforming.

- Compatibility: Suitable for handling spooled or coiled materials in various sizes and formats.

- Versatility: Used in applications such as extrusion lines, wire processing and optical fiber manufacturing.

- Automation Options: Many payoff winders integrate with automated systems for improved productivity and reduced downtime.

Benefits:

- Efficiency: Enables seamless feeding of materials into production lines.

- Quality Assurance: Prevents material damage through controlled unwinding.

- Cost-Effectiveness: Reduces waste by maintaining consistent material tension.

Modern payoff winders from Supertek are customizable to meet the specific needs of different industries, making them an essential component in high-precision production environments.