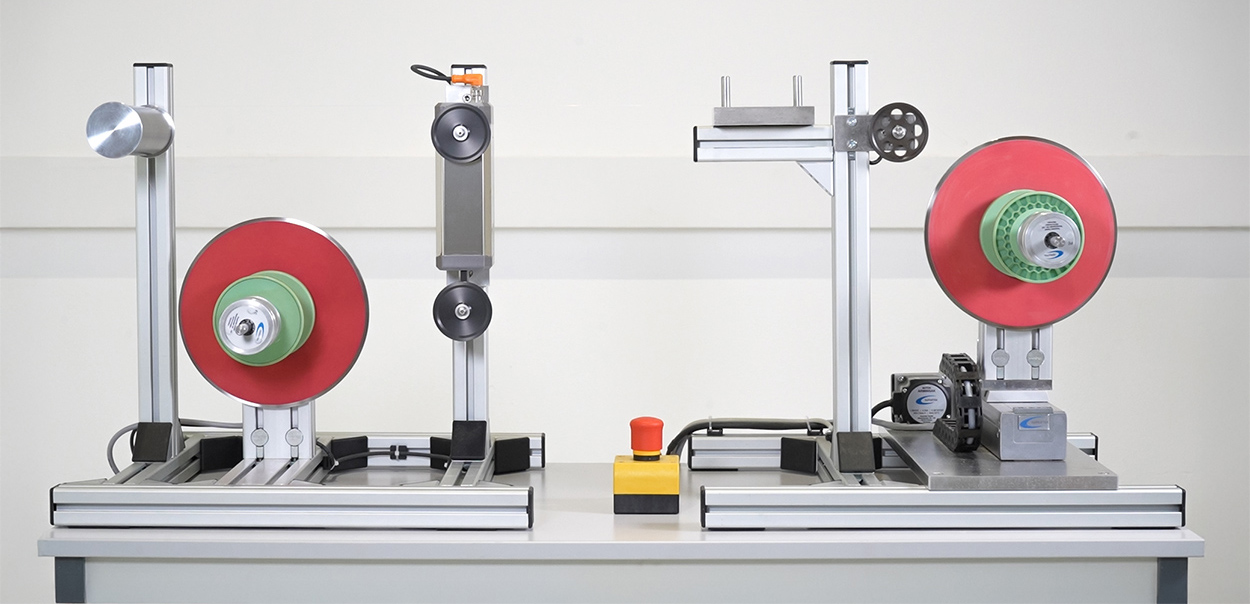

Rewinder

Explanation and Applications

A rewinder is an industrial machine designed to wind materials such as paper, labels, fiberglass, wire, and other similar materials onto rolls. These machines play a critical role in the further processing of materials and are commonly used in manufacturing and packaging industries. They help increase production speed and maximize efficiency when handling large quantities of materials.

How It Works

A rewinder works by taking material from a large master roll (or feed roll) and winding it onto smaller, more manageable rolls. During this process, the rewinder can make various adjustments, such as regulating the web width, material tension, or cutting lengths. Some models have special mechanisms for defect detection to discard faulty sections and ensure the quality of the final product. Other rewinders can also cut, package, or reformat the material into specific shapes or sizes.

Areas of Application

Rewinders are used in a variety of industries:

- Paper Industry: In this sector, rewinders are used to wind paper, cardboard, or other paper products from large rolls into smaller formats. They are also essential in the packaging industry for shaping packaging materials to the desired size.

- Label Production: In the label industry, rewinders are indispensable for creating label rolls for further transport or sale. Precise processing is critical here to ensure the production of flawless label rolls.

- Fiberglass Industry: Rewinders are used in the production of fiberglass cables or rolls, winding fiberglass fibers onto precise rolls for transport or further processing in other applications.

- Wire Processing: Rewinders are also used in wire processing to wind wires of various materials. These wires can then be used for a variety of applications, such as in the electrical or construction industries.

A rewinder is an incredibly versatile and indispensable device that not only enhances the efficiency of production processes but also ensures the quality and precision of the final products.

Advantages of a Rewinder

- Increased Efficiency: Automated winding and processing save time and labor.

- Flexibility: Modern rewinders can work with various materials and sizes.

- Cost Savings: By reducing material waste and improving production speed, companies can save costs.

- Precision: Rewinders enable precise material processing, which is especially important in the label and fiberglass industries.

Thanks to their versatility and precision, rewinders are indispensable in modern production processes and contribute to the optimization of the entire production chain.