Dancer Position Control

Dancer position control is based on slack control, with the crucial difference being that tensile force is regulated not by the product's own mass but by an external force acting on the product.

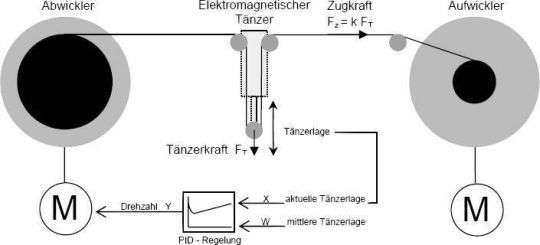

Dancer position control is a proven method for actively regulating the tensile force of wound products. Active tensile force control employs drive motors for general material transport, such as using a spool drive instead of braking systems. The schematic diagram illustrates the rewinding process of a wound product from unwinder to winder with dancer position control. In this diagram, the winder is assumed to wind the product at a specified speed. The unwinder must follow the winder to achieve the desired tension.

This is achieved by applying a force to the wound product via a movable guide roller, which corresponds to the tension in a fixed ratio. In the schematic diagram shown, positive acceleration of the winder would cause the movable guide roller to move upwards, while negative acceleration would cause it to move downwards. This up and down movement is also referred to as "dancing," hence the term "dancer." According to the principle of pulleys, the tensile force is proportional to the dancer force. The dancer position is used for speed control of the drive motor, preferably with a PID controller. If the dancer moves upwards, the control deviation leads to positive acceleration of the unwinder, and vice versa. To ensure that tensile force remains unchanged during control deviations, the dancer force must be kept constant regardless of dancer position.

Conventional dancer systems using weights, pneumatic cylinders, and/or springs can only achieve relatively coarse tensile force regulation with corresponding fluctuations. This limitation stems from the physical characteristics of dancer force. With weight-based dancers, force changes due to dancer movement according to F = ma. Inertia inevitably causes changes in tensile force. Springs always exert a force proportional to their length, contradicting the need for constant dancer force, which is also difficult to achieve with specialized pneumatic cylinders.

Conventional methods, particularly in the regulation of sensitive products' tensile force, have reached their technical limits. For this reason, Supertek GmbH has developed an electromagnetic dancer based on Supertek's patented electromagnetic force method, capable of generating highly dynamic and dancer-position-independent constant dancer force. With the electromagnetic dancer EDL 60, tensile forces ranging from 10 cN to 600 cN can be controlled with a resolution of 0.1 cN. Where other systems fail, the electromagnetic dancer enables even the most sensitive wound products to be processed quickly, precisely, and effortlessly.

Changes in dancer position should not alter tensile force but rather serve solely to regulate the drive motor.