Inline measurements of wire

Supertek designs and manufactures rewinding machines and inspection machines for quality control of wire, fine wire and flat wire. An important inspection of wire is the measurement of diameter and shape deviations. Simple defect detectors are often not sufficient for this purpose. Precision measuring devices, on the other hand, can measure the cross-sections from the wire in high resolution without contact. For precise inline measurement, Supertek integrates the appropriate measuring heads and measuring devices into the plant and automation software so that a response to the measurement results can be made in real time.

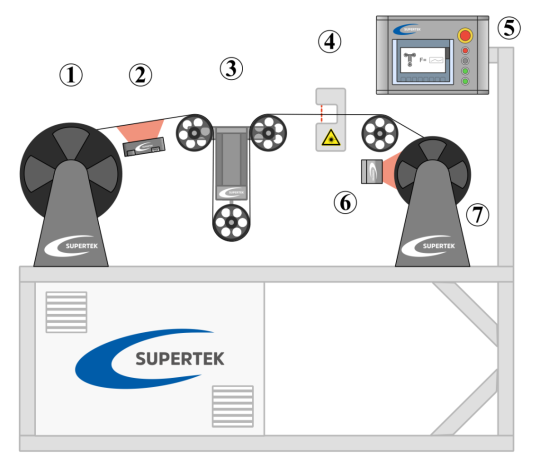

Rewinding machine for wire inspection.

High precision inspection machine

Rewinding machine for very thin wires with high quality requirements. The rewinding machine can automatically stop, rewind, and spool to a defined position depending on the measurement result. Furthermore, marking of the defect location of the wire or fiber is possible. For flat wire measurements, Supertek offers solutions for high precision inline measurement of the rectangular cross section. From Supertek you can get swiveling and rotating systems for inline measurement, which can rotate the measuring heads up to 360°.

Cleaning, straightening, marking, sorting, cutting to length or ejecting can also be implemented by our mechanical engineering department.

Operating principle for testing and surface inspection of wire with a rewinding machine.

- Unwinder

- Position scanner

- Electromagnetic Dancer

- Measuring device, sensor head

- HMI

- Coil Scanner

- Rewinder