Measurement Technology

For the controlled winding of wires and fibers, determining various physical quantities such as wire length, winding speed, or tension is necessary.

Measurement of Length and Speed

To measure these physical quantities—length, speed, and force—guide rollers can be used to guide the wire.

Force can be measured using tension sensors or load cells. Encoders or rotary encoders mounted on guide rollers are suitable for measuring speed and length.

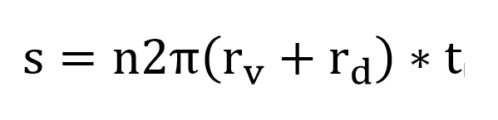

The length is calculated as follows:

Considerations include the rotational speed nnn of the guide roller, the radius rUr_UrU from the center of the guide roller to the running surface, and half of the wire diameter rDr_DrD, or the wire radius.

The wire diameter affects the measurement of length and speed and should be parameterizable for the HMI (Human-Machine Interface).

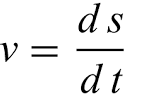

The speed vvv is calculated as follows:

The resolution and accuracy of length and speed determination depend on several factors such as the design of the guide roller, the type of speed measurement or resolution of the encoder, the frictional force (slip) between the guide roller and the material being measured, signal processing, and calculation time (real-time processing).

Supertek offers different guide rollers with encoders for speed measurement. The calculation of length and speed is performed in real-time with the Winding Controller MCU. This enables precise winding of a target length of material, which is crucial, for example, in the production of precision coils.

Tension Measurement

When implementing tension control with our electromagnetic dancers, additional force measurement with tension meters is not necessary. This is because the dancer force of the electromagnetic dancer works equivalently to a precision scale with electromagnetic force compensation.